Sea salt is one of the oldest and most natural ingredients in the world. From enhancing flavors in food to nourishing skincare routines, it has always held a special place in human life. But have you ever wondered how sea salt is actually made? This guide explains the step-by-step process of sea salt production, different types of sea salts, and how they compare to other salts like rock salt, Himalayan salt, and Epsom salt. By the end, you’ll have a complete understanding of its creation, benefits, and purity.

Table of Contents

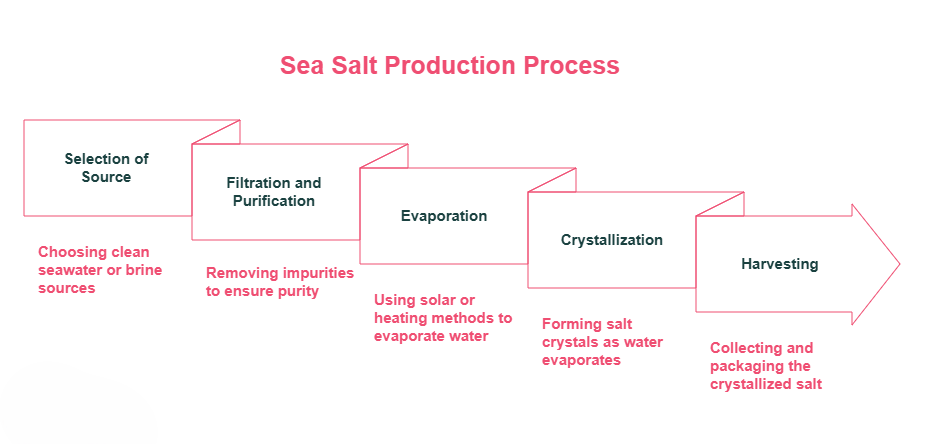

Step-by-Step Process of How Sea Salt Is Made

Making sea salt is a fascinating blend of nature and human skill. Here’s the step-by-step process:

Selection of Source

Sea salt begins with clean seawater or natural brine sources. It is collected from oceans, coastal regions, or saltwater lakes where pollution is minimal.

Filtration and Purification

The collected seawater is filtered to remove impurities such as sand, clay, or unwanted minerals. This ensures the purity of the final product.

Evaporation

- Solar Evaporation: In hot and windy climates, seawater is left in large open pans. The sun and wind naturally evaporate the water, leaving salt crystals behind. This is the oldest and most eco-friendly method.

In small-scale setups like those in the Philippines, producers can yield about 32.75 kg of sea salt per month from 300 liters of seawater over three cycles, with drying times of 7–19 days depending on weather conditions.[1] - Heating: In colder regions, seawater is heated in boilers to speed up evaporation.

The traditional solar evaporation process can take 3 to 5 years, from pumping seawater into ponds to harvesting crystals. This slow method allows natural concentration of minerals, giving sea salt its distinctive flavor.[2]

Crystallization

As water evaporates, salt begins to crystallize and settle at the bottom of pans. The texture and size of crystals vary depending on climate, temperature, and method used.

Harvesting

Once crystallized, salt is collected by hand or machinery. It is then washed, dried, and packaged for use. This harvested salt is what we know as sea salt.

In the United States, total salt production hit 42 million metric tons in 2023, with about 4.2 million tons (10%) coming from solar-evaporated sea salt in states like California and Utah.[3]

Explore: Process Of Himalayan Salt Mining

The Data Shows:

The global sea salt market stood at approximately $20.5 billion in 2024 and is expected to reach $27.8 billion by 2032, growing at a steady rate of about 3.89% annually, fueled by demand in food, cosmetics, and industrial applications. [4]

Different Types of Sea Salt Around the World

The region where sea salt is harvested influences its flavor, texture, and mineral content.

Mediterranean Sea Salt:

Light in texture with minerals like magnesium and calcium. Perfect for everyday cooking.

Atlantic Sea Salt:

Rich in flavor with varying mineral profiles based on the coastal region.

Pacific Sea Salt:

Harvested from the Pacific Ocean; often used for its delicate taste.

Celtic Sea Salt:

Celtic Sea Salt: A traditional French variety, known for its moist texture and grayish color, which comes from clay-lined salt ponds.A traditional French sea salt, known for its moist texture and grayish color due to clay-lined salt ponds. Celtic sea salt can be purified to a near-perfect 99.5% sodium chloride, trimming minerals like magnesium and calcium to trace amounts comparable to Himalayan salt’s purity.[5]

Explore: what is Celtic sea salt

Variations in Texture, Color, and Taste

Texture:

Fine sea salt dissolves quickly and is used in baking or seasoning, while coarse sea salt is ideal as a finishing salt.

Color:

Natural minerals can give sea salt shades of white, pink, gray, or even black.

Taste:

Depending on the minerals, sea salt may taste briny, earthy, or slightly sweet.

Difference Between Rock Salt and Sea Salt

Understanding the difference between rock salt and sea salt helps in choosing the right one for your needs:

- Origin: Rock salt is mined from ancient underground salt deposits, while sea salt is made by evaporating seawater.

- Minerals: Rock salt often contains fewer trace minerals, whereas sea salt is rich in natural minerals from the ocean.

- Uses: Rock salt is commonly used for de-icing roads and in some culinary uses, while sea salt is popular for cooking, finishing, and skincare.

Read About: Rock Salt Vs. Sea Salt

Is Celtic Sea Salt Better Than Himalayan Salt?

This is a common comparison for health-conscious consumers:

- Celtic Sea Salt: Contains essential minerals and is slightly moist, making it flavorful.

- Himalayan Salt: Mined from ancient deposits, pink in color due to iron oxide, and known for its purity.

Both are rich in minerals and occur naturally. Which one to choose is a matter of intended use and individual taste preference. Reliable companies like Sobaan Salts guarantee authenticity of both Celtic and Himalayan salts ensuring quality.

Read About: Celtic Sea Salt Vs Himalayan Salt

Is Sea Salt the Same as Epsom Salt?

No. Sea salt and Epsom salt are completely different:

- Sea Salt: Made of sodium chloride (NaCl). Typically contains 80–85% sodium chloride along with natural trace minerals [6], used for cooking, skincare, and wellness.

- Epsom Salt: Made of magnesium sulfate (MgSO4), not suitable for cooking, but commonly used for baths and therapeutic purposes.

Mixing them up can lead to health risks, so always check the packaging before use.

Read About: Dead Sea Salt Vs Epsom Salt

Does Sea Salt Expire?

Pure salt never truly expires, but improper storage can affect its quality and usability.

- Shelf Life: Sea salt can last indefinitely if stored correctly.

- Storage Tips: Keep in an airtight container, away from moisture and direct sunlight. Proper drying ensures harmful microbes stay below 10,000 CFU per gram, keeping sea salt safe for years. [7]

- Signs of Spoilage: Clumping or unusual odor may indicate contamination, not expiration.

Explore:

Does Himalayan Salt Expire

Does Black Salt Expire

Does Kosher Salt Expire

Importance of Purity and Quality Control

High-quality sea salt requires strict purity measures:

- Clean Collection Sites: Seawater must be sourced from unpolluted areas.

- Testing and Monitoring: Regular lab checks ensure safety and taste.

- Environmental Care: Responsible harvesting reduces harm to marine ecosystems.

That’s why sourcing sea salt from trusted suppliers like Sobaan Salts guarantees purity, quality, and sustainability.

Quick Comparison Table: Types of Salt

Type of Salt | Source | Main Minerals | Common Uses |

Sea Salt | Evaporated seawater | Sodium, magnesium, Ca | Cooking, skincare, baths |

Rock Salt | Underground deposits | Mainly sodium chloride | De-icing, cooking |

Celtic Sea Salt | French coast | Sodium, trace minerals | Gourmet cooking, finishing |

Himalayan Salt | Pakistan (Khewra) | Sodium, iron, Ca, Mg | Cooking, lamps, decor |

Epsom Salt | Mineral springs | Magnesium sulfate | Baths, therapeutic use |

Conclusion

To sum up, sea salt is made by collecting clean seawater, filtering it, then allowing it to evaporate and crystallize before harvesting and packaging. Collecting sea water, region, mineral content, and climate shape the flavor and texture of the sea salt.

Celtic, Mediterranean, or Tibetan Himalayan, it is always the quality, purity, and authenticity of the salt which is most important. Suppliers like Sobaan Salts guarantee that every grain is natural, safe, and filled with salt goodness.

Now with this information, sea salt is more than just seasoning, it’s a natural product that goes through a long process before it lands on the dining table.

The global sea salt market is projected to reach $13.2 billion by 2027, growing at a CAGR of 6.5% from 2022, driven by its use in culinary, skincare, and wellness applications, aligning with the blog’s focus on sea salt’s natural production and diverse uses. Source: IndustryArc

References:

- Maldon Salt – A Guide to Sea Salt: How It’s Made & Where It Comes From

- Health.com – Himalayan Salt vs. Sea Salt: What’s the Difference?

- EcoWatch – 7 Different Kinds of Salt and How to Use Them

Share This Post

Article By